Airbus to test hydrogen engine on A380 jumbo jet

By Alex Macheras

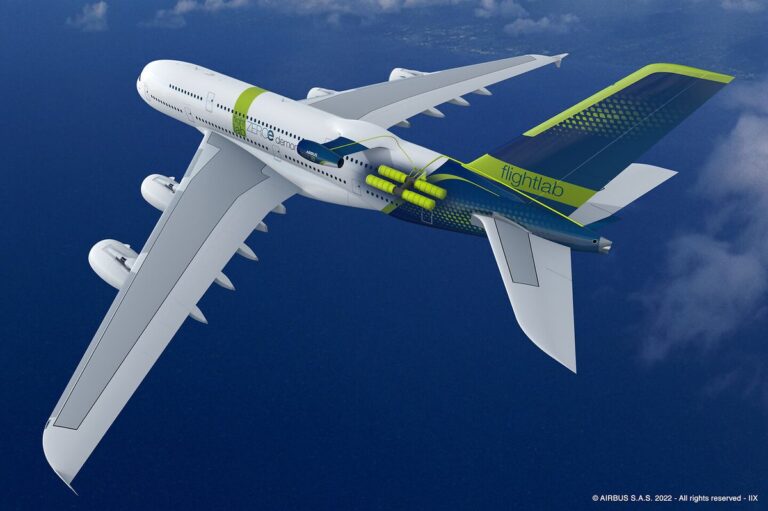

Airbus this week announced it will modify a superjumbo A380 to test a hydrogen-powered jet engine as the European aerospace group prepares to bring a zero emissions aircraft into service by 2035.

The partnership is an agreement with CFM International, a 50/50 joint company between GE and Safran Aircraft Engines, to develop an engine that can run on hydrogen. The converted test aircraft, the A380, will fly by the end of 2026.

The programme’s objective is to ground and flight test a direct combustion engine fuelled by hydrogen, which Airbus is betting on to enable the company to decarbonise in line with aviation’s climate change goals. The A380 flying test jet will be equipped with liquid hydrogen tanks prepared at Airbus facilities in France and Germany. Airbus will also define the hydrogen propulsion system requirements, oversee flight testing, and provide the A380 platform to test the hydrogen combustion engine in cruise phase.

CFM International will modify the combustor, fuel system, and control system of a GE Passport turbofan to run completely on hydrogen. The engine itself will be mounted along the rear fuselage of the A380 test jet to allow engine emissions, including contrails, to be monitored separately from those of the engines powering the aircraft.

“This is the most significant step undertaken at Airbus to usher in a new era of hydrogen-powered flight since the unveiling of our ZEROe concepts back in September 2020,” said Sabine Klauke, Airbus chief technical officer. “By leveraging the expertise of American and European engine manufacturers to make progress on hydrogen combustion technology, this international partnership sends a clear message that our industry is committed to making zero-emission flight a reality.”

The venture comes amid increasing pressure on the aviation industry to cut pollution and meet zero-emission targets by 2050. Before the pandemic led to the grounding of much of the world’s aircraft, aviation accounted for roughly 2.4% of global emissions. “To achieve these goals by 2050 the industry has to take action now and we are,” said Gael Meheust, chief executive of CFM.

“Is hydrogen harder? Yes. Is it do-able? Absolutely,” said Mohamed Ali, vice-president and general manager of engineering at GE Aviation.

Executives said the decision to use an A380, the world’s largest passenger airline jet that has been phased-out at many airlines around the world due to its inefficiencies, would allow engineers more room for things like the tanks and the testing equipment. A commercial product available to airlines over the coming years will be much smaller. Airbus is expected to initially produce a regional or shorter-range aircraft.

In today’s aircraft, wings are where the fuel is stored, and they are in no way large enough to store the hydrogen that would be needed for a long flight. Hydrogen planes of the future could have extra-large fuselages, but more likely they will be what’s called blended wing, in which the planes are shaped like large triangles. This would allow them to store more fuel, but also reduce fuel consumption to make the aircraft aerodynamics even better.

Planes using hydrogen would emit only water, and initial tests suggest they can be just as fast as traditional planes, carrying more than a hundred passengers per flight over thousands of kilometres.

Most of the world’s hydrogen today is produced by reforming methane from natural gas – a fossil fuel – which produces carbon dioxide. Efforts are underway to develop green hydrogen by using an electric current from a renewable source to convert water into oxygen and hydrogen and reduce emissions in its production. If that is possible, along with no emissions from the planes themselves, aviation could become a green form of travel.

There are significant challenges that remain. If Europe were to fully achieve the environmental benefits of hydrogen-power – for example, for air travel, the production of clean – or green – hydrogen needs to be dramatically scaled up. Clean hydrogen is produced from water using an electric current from a renewable source, rather than from fossil fuels. Today only a tiny fraction of hydrogen used in Europe is categorically “clean.”

Hydrogen is a high-potential technology with a specific energy-per-unit mass that is three times higher than traditional jet fuel. Airbus notes that, if generated from renewable energy through electrolysis, given the fact it emits no CO2 emissions, it will enable renewable energy to potentially power large aircraft over long distances but without the undesirable by-product of CO2 emissions.

For now, we are still years away from commercial hydrogen aircraft becoming a reality, though. The refuelling infrastructure doesn’t exist yet and hydrogen is more expensive and difficult to store onboard than kerosene-based fuel.

“Hydrogen combustion capability is one of the foundational technologies we are developing and maturing as part of the CFM RISE Programme,” said Gaël Méheust, president & CEO of CFM. “Bringing together the collective capabilities and experience of CFM, our parent companies, and Airbus, we really do have the dream team in place to successfully demonstrate a hydrogen propulsion system.”

Boeing has focused on more sustainable aviation fuels, which currently make up less than 1% of the jet fuel supply and are more expensive than conventional jet fuel. CEO Dave Calhoun said at an investor conference that he didn’t expect a hydrogen-powered plane on “the scale of airplanes that we’re referring to” before 2050.

Sustainable Aviation Fuel is a clean substitute for fossil jet fuels. Rather than being refined from petroleum, SAF is produced from sustainable resources such as waste oils from a biological origin, or non-fossil CO2. It is a so-called drop-in fuel, which means that it can be blended with fossil jet fuel and that the blended fuel requires no special infrastructure or equipment changes. It has the same characteristics and meets the same specifications as fossil jet fuel.

Since the first commercial flight operated by KLM in 2011, more than 150,000 flights were powered by SAF. More than 45 airlines now have experience with SAF, and around 14bn litres of SAF are in forward purchase agreements.

Several airlines are driving forward the use of SAFs by signing multi-million dollar forward purchasing agreements. Others have invested in start-up support for SAF deployment, and some have promoted SAFs through test flights, research, and investigation of local opportunities. Five airports also have a regular SAF supply: San Francisco, Los Angeles, Oslo, Bergen and Stockholm.

However, scaling up the use of SAFs to a global market is challenging and requires substantial investment. The industry has called on governments to assist potential SAF suppliers to develop the necessary feedstock and refining systems – at least until the fledgling industry has achieved the necessary critical mass and prices drop thanks to economies of scale.* The author is an aviation analyst. Twitter handle: @AlexInAir

The partnership is an agreement with CFM International, a 50/50 joint company between GE and Safran Aircraft Engines, to develop an engine that can run on hydrogen. The converted test aircraft, the A380, will fly by the end of 2026.

The programme’s objective is to ground and flight test a direct combustion engine fuelled by hydrogen, which Airbus is betting on to enable the company to decarbonise in line with aviation’s climate change goals. The A380 flying test jet will be equipped with liquid hydrogen tanks prepared at Airbus facilities in France and Germany. Airbus will also define the hydrogen propulsion system requirements, oversee flight testing, and provide the A380 platform to test the hydrogen combustion engine in cruise phase.

CFM International will modify the combustor, fuel system, and control system of a GE Passport turbofan to run completely on hydrogen. The engine itself will be mounted along the rear fuselage of the A380 test jet to allow engine emissions, including contrails, to be monitored separately from those of the engines powering the aircraft.

“This is the most significant step undertaken at Airbus to usher in a new era of hydrogen-powered flight since the unveiling of our ZEROe concepts back in September 2020,” said Sabine Klauke, Airbus chief technical officer. “By leveraging the expertise of American and European engine manufacturers to make progress on hydrogen combustion technology, this international partnership sends a clear message that our industry is committed to making zero-emission flight a reality.”

The venture comes amid increasing pressure on the aviation industry to cut pollution and meet zero-emission targets by 2050. Before the pandemic led to the grounding of much of the world’s aircraft, aviation accounted for roughly 2.4% of global emissions. “To achieve these goals by 2050 the industry has to take action now and we are,” said Gael Meheust, chief executive of CFM.

“Is hydrogen harder? Yes. Is it do-able? Absolutely,” said Mohamed Ali, vice-president and general manager of engineering at GE Aviation.

Executives said the decision to use an A380, the world’s largest passenger airline jet that has been phased-out at many airlines around the world due to its inefficiencies, would allow engineers more room for things like the tanks and the testing equipment. A commercial product available to airlines over the coming years will be much smaller. Airbus is expected to initially produce a regional or shorter-range aircraft.

In today’s aircraft, wings are where the fuel is stored, and they are in no way large enough to store the hydrogen that would be needed for a long flight. Hydrogen planes of the future could have extra-large fuselages, but more likely they will be what’s called blended wing, in which the planes are shaped like large triangles. This would allow them to store more fuel, but also reduce fuel consumption to make the aircraft aerodynamics even better.

Planes using hydrogen would emit only water, and initial tests suggest they can be just as fast as traditional planes, carrying more than a hundred passengers per flight over thousands of kilometres.

Most of the world’s hydrogen today is produced by reforming methane from natural gas – a fossil fuel – which produces carbon dioxide. Efforts are underway to develop green hydrogen by using an electric current from a renewable source to convert water into oxygen and hydrogen and reduce emissions in its production. If that is possible, along with no emissions from the planes themselves, aviation could become a green form of travel.

There are significant challenges that remain. If Europe were to fully achieve the environmental benefits of hydrogen-power – for example, for air travel, the production of clean – or green – hydrogen needs to be dramatically scaled up. Clean hydrogen is produced from water using an electric current from a renewable source, rather than from fossil fuels. Today only a tiny fraction of hydrogen used in Europe is categorically “clean.”

Hydrogen is a high-potential technology with a specific energy-per-unit mass that is three times higher than traditional jet fuel. Airbus notes that, if generated from renewable energy through electrolysis, given the fact it emits no CO2 emissions, it will enable renewable energy to potentially power large aircraft over long distances but without the undesirable by-product of CO2 emissions.

For now, we are still years away from commercial hydrogen aircraft becoming a reality, though. The refuelling infrastructure doesn’t exist yet and hydrogen is more expensive and difficult to store onboard than kerosene-based fuel.

“Hydrogen combustion capability is one of the foundational technologies we are developing and maturing as part of the CFM RISE Programme,” said Gaël Méheust, president & CEO of CFM. “Bringing together the collective capabilities and experience of CFM, our parent companies, and Airbus, we really do have the dream team in place to successfully demonstrate a hydrogen propulsion system.”

Boeing has focused on more sustainable aviation fuels, which currently make up less than 1% of the jet fuel supply and are more expensive than conventional jet fuel. CEO Dave Calhoun said at an investor conference that he didn’t expect a hydrogen-powered plane on “the scale of airplanes that we’re referring to” before 2050.

Sustainable Aviation Fuel is a clean substitute for fossil jet fuels. Rather than being refined from petroleum, SAF is produced from sustainable resources such as waste oils from a biological origin, or non-fossil CO2. It is a so-called drop-in fuel, which means that it can be blended with fossil jet fuel and that the blended fuel requires no special infrastructure or equipment changes. It has the same characteristics and meets the same specifications as fossil jet fuel.

Since the first commercial flight operated by KLM in 2011, more than 150,000 flights were powered by SAF. More than 45 airlines now have experience with SAF, and around 14bn litres of SAF are in forward purchase agreements.

Several airlines are driving forward the use of SAFs by signing multi-million dollar forward purchasing agreements. Others have invested in start-up support for SAF deployment, and some have promoted SAFs through test flights, research, and investigation of local opportunities. Five airports also have a regular SAF supply: San Francisco, Los Angeles, Oslo, Bergen and Stockholm.

However, scaling up the use of SAFs to a global market is challenging and requires substantial investment. The industry has called on governments to assist potential SAF suppliers to develop the necessary feedstock and refining systems – at least until the fledgling industry has achieved the necessary critical mass and prices drop thanks to economies of scale.* The author is an aviation analyst. Twitter handle: @AlexInAir